C-Innovation is the leader in Remotely Operated Vehicle (ROV) systems for the oil and gas industry. The C-Innovation brand is backed by being the largest owner and operator of Schilling Robotics ROV systems in the world. With the support of Schilling Robotics, C-Innovation provides a range of specialized remote diagnostic and mission-planning software, as well as proprietary Augmented Reality and Mid-Water StationKeep™ systems. Our submarine ROV technological capabilities offer clients a robust, system-wide platform utilizing the most sophisticated ROVs on the market, along with superior sensor capacity.

The main contributing factor to our ROV system success and repeat work internationally is our offshore ROV personnel. Their knowledge, experience and dedication directly contribute to projects. Our ROV crews work through challenges daily, and their commitment to performing at a level that exceeds expectations is highly appreciated by clients.

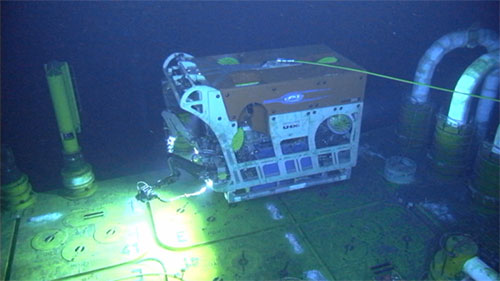

C-Innovation stands ready to deploy the most advanced work-class ROVs to major operators of the industry.

OUR ROV FLEET

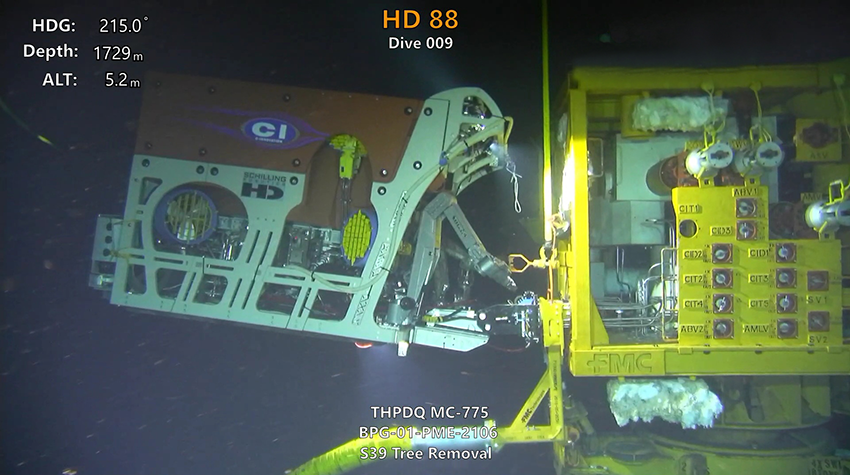

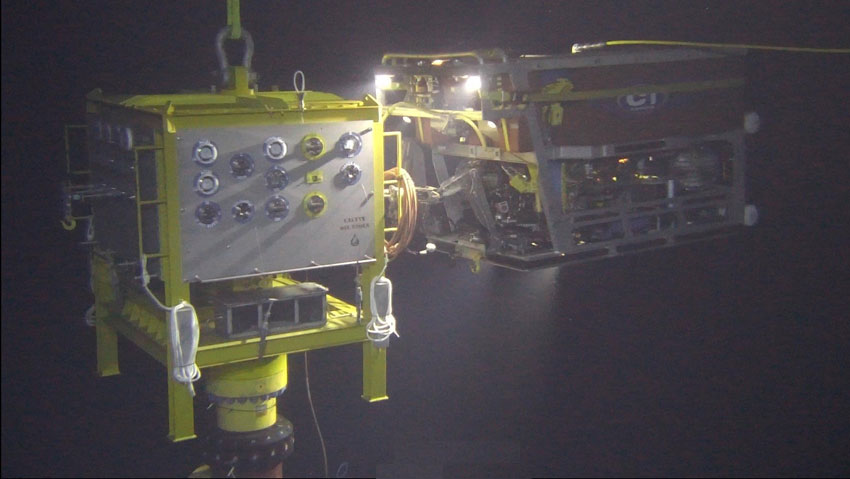

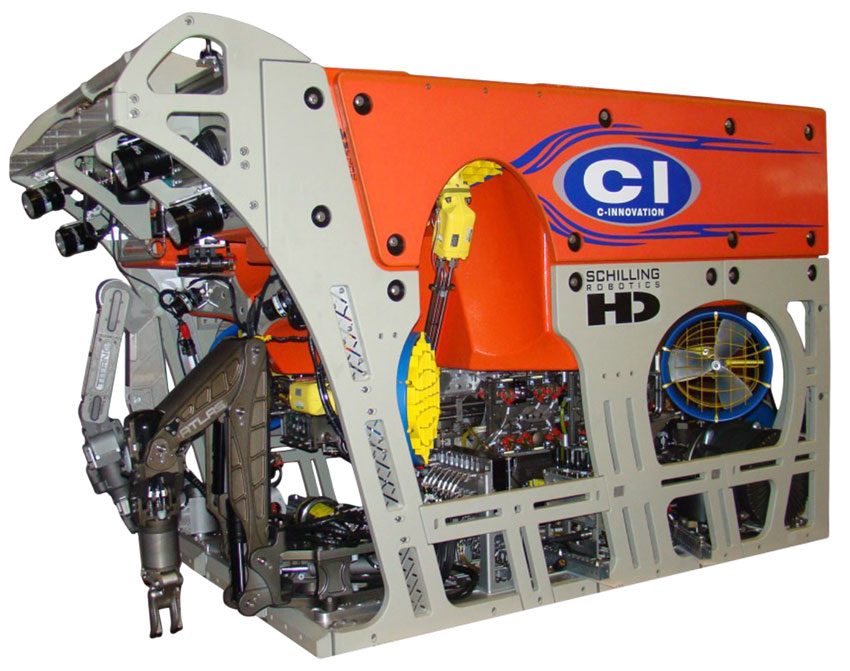

Heavy Duty (HD)

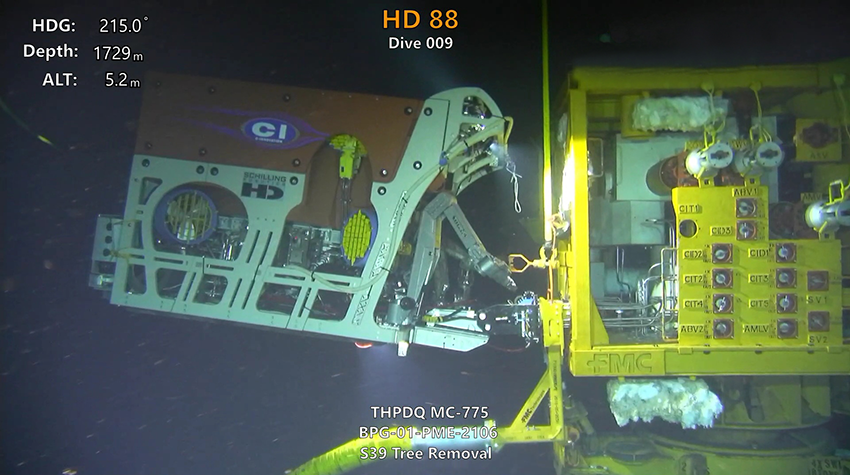

The Heavy Duty (HD) ROV has a smaller design while still executing at high performance for subsea operations, making this ROV ideal for manipulating tight spaces. Designed with the most advanced technology, this ROV system leads the industry in reliability and performance. The modular design of the vehicle decreases maintenance time by a factor of 6-to-1 compared to standard industry vehicles. As for environmental impact, the stainless-steel tubing used throughout the hydraulic system offers the most reliable method to avoid leakage.

Schilling Robotics

Heavy Duty (HD)

Work Class ROV

- HP: 150

- Depth Rated: 3,000m

- Dimensions: 8’ L x 5.5’ W x 6.2’ H

- Maximum Speed: Fwd-3.2 kts. x Lat-2.3 kts. x Ver-2.4 kts.

- Bollard Pull: Fore/Aft-1984 lbf, Lat-1984 lbf, Ver-1874 lbf

- Payload: 551 lbs.

- Station Keeping: 3.9” Watch Circle

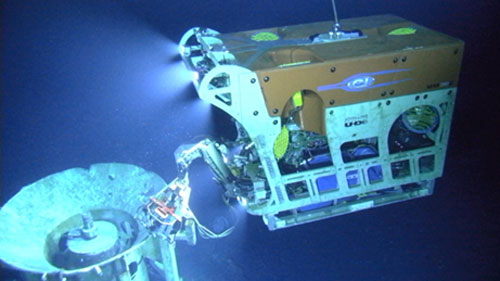

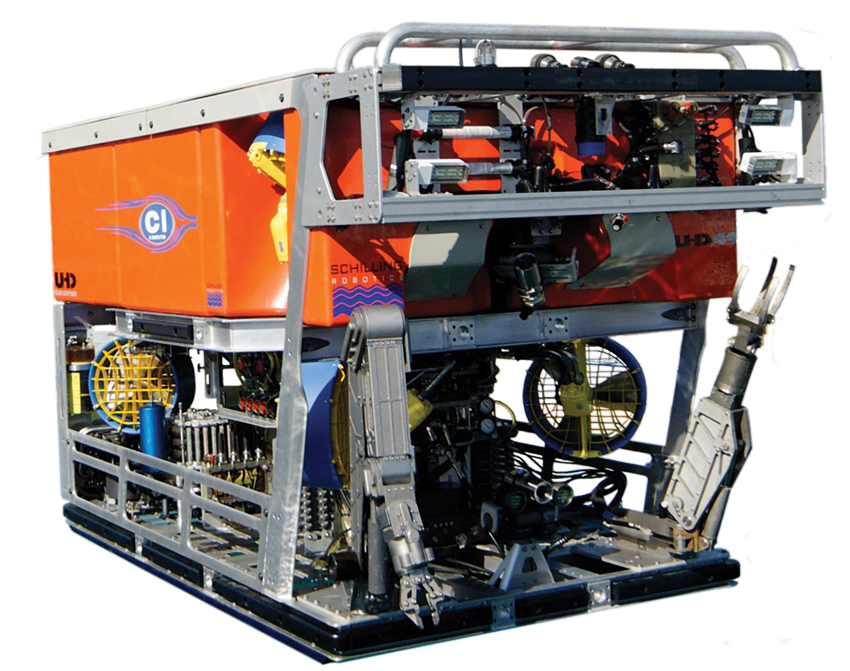

Ultra Heavy Duty (UHD)

The Ultra Heavy Duty (UHD) ROV is optimized for efficient tooling and sensor interfaces with unlimited data or video channels that are easily customizable. This state-of-the-art ROV features an advanced control system with many closed loop functions, as well as specialized StationKeep™ software to allow operations to automatically maintain a position relative to the sea floor. Additionally, this ROV control system possesses a power management system that delivers power where required to perform ROV operations in extreme situations.

Schilling Robotics

Ultra Heavy Duty (UHD)

Gen I & II Work Class ROV

- HP: 200

- Depth Rated: 4,000m

- Dimensions: 9.8’ L x 6.2’ W x 6.5’ H

- Maximum Speed: Fwd-3.2 kts. x Lat-2.3 kts. x Ver-2.4 kts.

- Bollard Pull: Fore/Aft-1984 lbf, Lat-1984 lbf, Ver-1874 lbf

- Payload: 661 lbs.

- Station Keeping: 3.9” Watch Circle

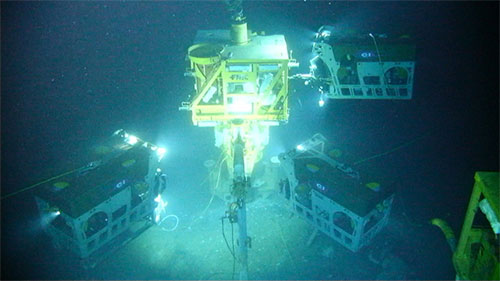

Ultra Heavy-Duty X-Treme

The Ultra Heavy-Duty X-Treme ROV by Schilling Robotics is a powerful ROV with an advanced control system, and plenty of payload to perform any subsea task efficiently and with ease. Its modular configuration decreases maintenance time 6-to-1 compared to standard industry vehicles. Integrated into this submarine ROV is the state-of-the-art ISOL pump, an isolated hydraulic power unit that redefines ROV fluid intervention. The UHD X-Treme has the capacity to meet API 53 requirements for BOP intervention.

Schilling Robotics

Ultra Heavy Duty (UHD)

Gen III Work Class ROV

- HP: 250

- Depth Rated: 4,000m

- Dimensions:11.5’ L x 6.2’ W x 6.9’ H

- Maximum Speed: Fwd-3.2 kts. x Lat-2.3 kts. x Ver-2.5 kts.

- Bollard Pull: Fore/Aft-2646 lbf, Lat-2646 lbf, Ver-2205 lbf

- Payload: 992 lbs.

- Station Keeping: 3.9” Watch Circle

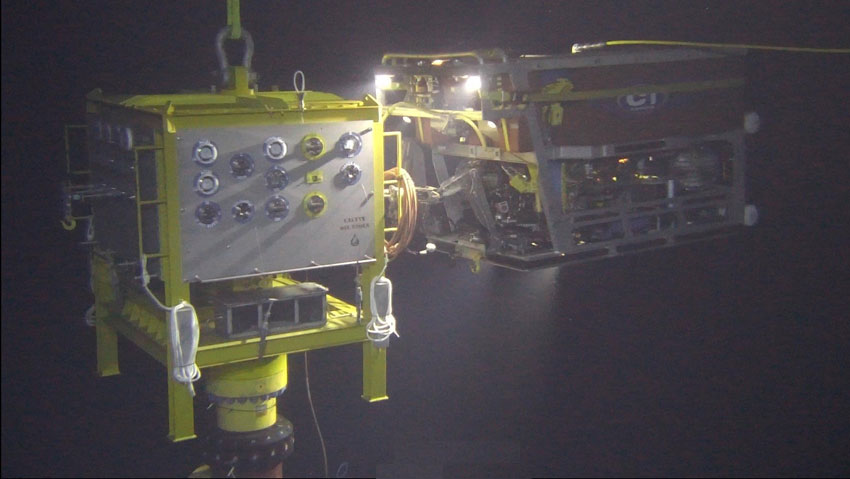

RELIABLE LAUNCH AND RECOVERY EQUIPMENT

Two Gamechangers: LARS and TMS

C-Innovation uses two systems – the LARS (Launch and Recovery System) and TMS (Tether Management System) – to successfully launch and recover from the vessel’s side, stern or internal moon pool. C-Innovation employs active heave compensated winches and several different styled A-frames in order to continue work subsea while overcoming the limitation of weather.

CUSTOMER TESTIMONIAL

“All of the ROV team onboard during operations performed SAFELY and PROACTIVELY. Many thanks for the job WELL DONE!”

BY THE END OF 2022

24 ROVs in Operation

C-Innovation is expected to reach 24 full time contracts for operating ROVs in Brazil by the end of 2022. We continue to meet and exceed our clients’ high expectations in the ROV market.

KEY PROJECTS

- C-Innovation Successfully Completes Stem Clamp Installation on BP’s Mad Dog SparC-Innovation, LLC (C-I), an affiliate of Edison Chouest Offshore (ECO) and its family of companies, has completed the installation of several stem clamps for BP beneath the Mad Dog Spar in the Gulf of Mexico, utilizing its subsea inspection, maintenance and repair (IMR) remotely operated vehicle (ROV) vessel, MV Dove. Throughout the planning process, several risks… Read More

- Flowline Hydrate RemediationClient: W&T Offshore Project: Fastball Flowline Hydrate Remediation Scope of Work Remediation/removal of complete hydrate blockage and flushing of flowline to satisfy government requirements for decommissioning was performed. The project took 19 days to complete. The tie-back well had already been de-completed and the jumper removed. Access was through a high-flow Hotstab port on a… Read More

- Acid Stimulation of WellsClient: Anadarko Petroleum Company (APC) Project: Acid Stimulation of Wells Location: KC875 #1 (Lucius), GC770 #1 (Caesar-Tonga), and GC683 #3 (Caesar-Tonga) Scope of Work The prescribed acid treatment to stimulate each well was pumped down dual, open-water coiled tubing (CT) downlines to the subsea well location. The TEI 15K STIM package was used to… Read More

- Flowline Segment Hydrate RemediationClient: Eni Petroleum Project: Longhorn Flowline Segment Hydrate Remediation Location: Gulf of Mexico, Mississippi Canyon, Block 502 Scope of work The primary objective of this project was to clear the flowline of a hydrate blockage to restore production from well #3. The extent of hydrate formation was unknown. The only access was through 1”… Read More